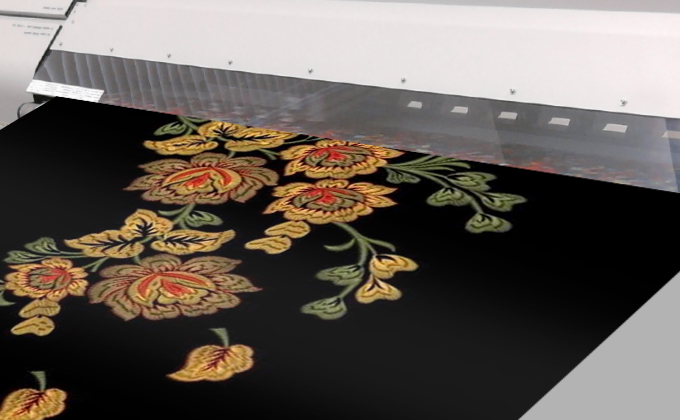

Applicable fabric

It can be used for digital printing of cotton, blended and silk fabrics, suitable for direct printing of clothing materials, decorative fabrics, garments, luggage, shoe materials, etc.;

For example: flags, carpets, swimwear, polyester non-woven bags, needle hats, tents, table mats, etc.

Applicable models

Applicable to EPSON/Epson head modified flat board/treadmill

Suitable for EPSON flatbed printers

Suitable for BROTHER Direct Injection Printing Machine

Advantages of product grouping

1. Textile direct ink is suitable for cotton cloth or pure cotton with more than 50% cotton

2. The light fastness reaches 7-8 grades, and the color fastness is high

3. The washing fastness reaches 4-5 grades, washing process, no fading

4. Environmentally friendly, non-toxic, tasteless and glue-free!