Printed products are soft to the touch and have a long service life

The biggest feature of sublimation transfer printing is that the dye can diffuse into polyester or fiber, and the printed product feels very soft and comfortable, and the existence of the ink layer is basically not felt. In addition, since the ink has already dried during the transfer printing process, the life of the image is as long as the life of the garment itself, and there will be no wear and tear of the printed graphics, which will affect the beauty of the fabric.

Wide range of applications

In addition to fabrics (non-cotton light-colored clothes), it can also be transferred to leather, metal, wood, ceramics, glass, plexiglass, PVC plates and other products. The main feature of sublimation transfer printing technology is that the transfer image is bright in color and rich in layers, and the effect is comparable to that of printing. The difference from printing is that the dye in the transfer ink is sublimated by heat, penetrates into the surface of the object, and forms a brightly colored image after sublimation. So the heat transfer products are durable and the images will not peel off, crack and fade.

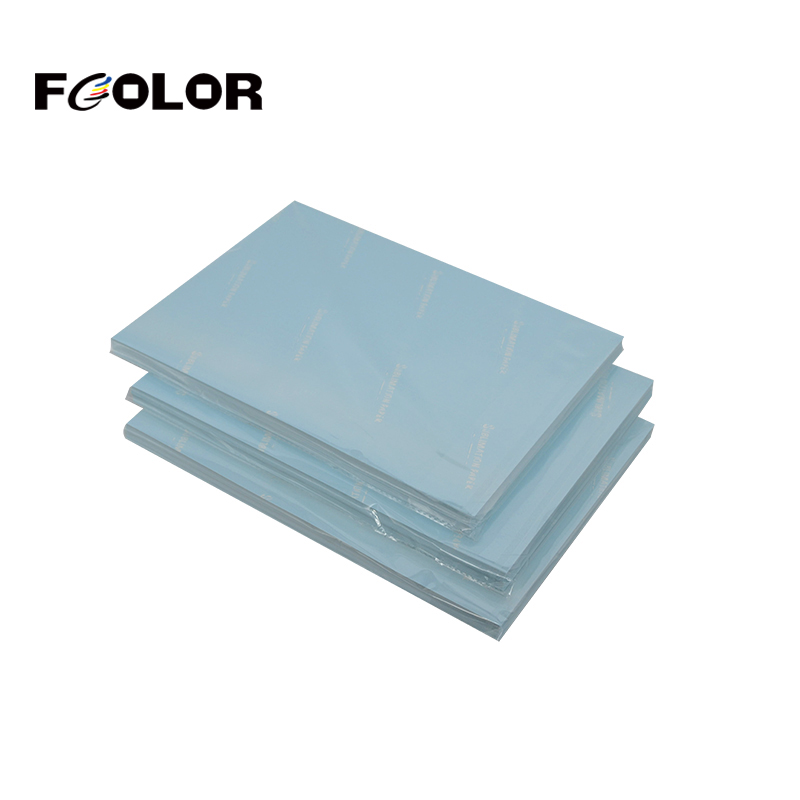

Advantages of sublimation ink

1. High thermal transfer rate

2. Bright colors: excellent color saturation and depth, high degree of reproduction

3. Fluency: the ink dispersion system is stable and the fluidity is good

4. Washing fastness: Perspiration fastness and rubbing fastness both reach above grade 4~5

5. Light fastness: extremely high light fastness, CMYK can reach level 7 or above

6. Safety and environmental protection: its chemical composition meets the requirements of SGS safety chemicals