can uv flatbed printers print embossed effects?

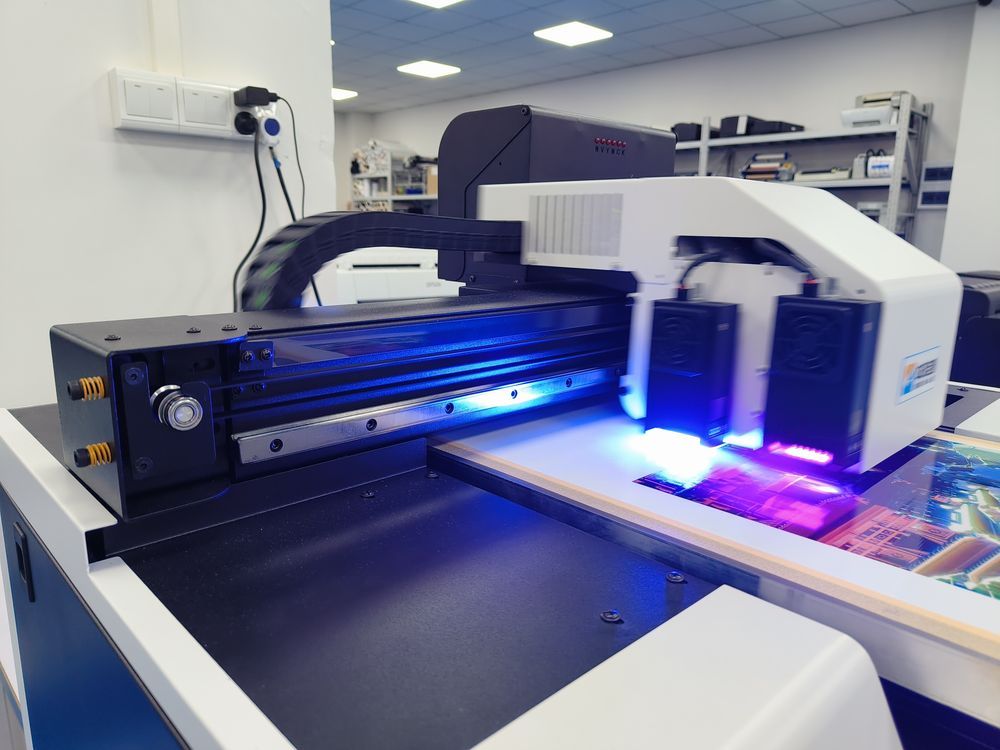

Having an embossed effect on the print will make the product look more three-dimensional. It is raised from the surface and gives a relief touch. In the current printing industry, printing using the UV process can do this. One of the most common types of equipment is the UV flatbed printer.

These printers will use a technique called thick ink printing to achieve the embossed effect. I will explain each of these below.What Is Thick Ink Printing in UV Flatbed Technology?

What Is Thick Ink Printing in UV Flatbed Technology?

Thick Ink Mode is also called Thick Ink Mode. By adjusting the amount of UV ink used for each print, the printer creates a layer of ink on the surface. The result? A raised texture effect that feels like a miniature sculpture.

This is especially noticeable on text, bold graphics and sharp edges, where the ink creates clear, tactile borders. But this mode also means print speeds won't be too fast.

Specialized UV Inks for Better Results

Some UV printers use specially formulated UV inks. These inks hold their shape without running and are more helpful in producing an embossed effect. When printing on smooth surfaces, these inks are essential if you want the ink to stay exactly where it is placed.

How Do You Control the Embossing Effect?

It's not just a matter of adding more ink to achieve an embossed effect. If you think so, then you're going to have a lot of problems with the printing process. Specific control of embossing also requires you to make some fine-tuning of the printer. For example, the following operations:

Adjusting Resolution and Layering

To achieve a quality embossed finish, operators often reduce the resolution and slow down the print speed. This allows more ink to accumulate in a single spot without spreading out.

Some advanced UV flatbed printers also support layer-by-layer printing. That means they can print one thin layer of ink, cure it, and then print another on top—repeating the process until the desired height is reached. The result is a very precise and refined raised effect.

Post-Print Finishing

Once the print is done, you can take the effect even further. Heat treatment or UV curing helps solidify and sharpen the embossed look. Adding a layer of clear varnish or gloss coating can also enhance the depth and bring out highlights.

Where Are Embossed UV Prints Used?

The applications for this type of printing are diverse and often visually stunning. Here are a few common uses:

1. Signage and Decorative Panels

Embossed logos and text add a luxurious, high-end feel to business signs and display boards. They're eye-catching and make the branding unforgettable.

2. Customized Gifts and Awards

Think personalized trophies, nameplates, keychains, or photo frames. The 3D ink brings a layer of sophistication and craftsmanship to gift items.

3. Premium Packaging

In product packaging, embossed effects help elevate the perceived value. Consumers associate depth and texture with quality—and that can translate into stronger shelf appeal.

4. Art and Creative Design

Artists and designers are increasingly using UV printers to create textured art pieces. Whether it’s a canvas or a mixed-media installation, raised ink brings a new dimension to creativity.

A Few Things to Watch Out For

Artists and designers are increasingly using UV printers to create textured art pieces. Whether it’s a canvas or a mixed-media installation, raised ink brings a new dimension to creativity.

Ink Thickness Balance

Applying too much ink too quickly can cause the print to look rough or messy, and in extreme cases, it can even disrupt the printer’s function. It’s all about striking the right balance between visual impact and technical control.

Material Compatibility

Not every surface handles thick UV ink the same way. Paper, PVC, acrylic, and wood tend to work well. But smooth or non-porous materials like metal might need pre-treatment or adhesion promoters to help the ink stick and build up correctly.

Printer Capability

It’s important to note: not all UV flatbed printers are capable of high-quality embossing. You’ll need a machine that supports thick ink printing, has a high-resolution print head, and allows precise control over ink layers. If embossing is a key requirement for your business, make sure your printer is up for the task.